The carbide lamps encyclopaedia

To know, use and restore the carbide lamps

- pages translated by a translation software -

![]() acethylene.com

acethylene.com

![]()

LAMPS and UNDERGROUND LIGHTING

acetylene gas lamp - Carbide lamps - Miner's lamps - safety lamps

www.acethylene.com - www.explographies.com -

www.geopedia.fr

Texts,

photos and documents

copyrighted.

© explographies.com - All rights reserved - Publication, total or partial reproduction prohibited.

explographies. - cube - acethylene - igc-maps - quarries & catacombs - atlas 1855 - cartographies - geology - topos & history - room K - geopedia

![]()

![]() index

index

![]()

carbide lamps & acetylene gas lamp

|

|

|

||||||||

|

|

|||||||||

History and use carbide lamps |

|

How does work a carbide lamp ? |

|

Discover a lamp First use |

|

Maintenance lamps |

Using advices Storage of carbide |

Buy and estimate lamps |

||

|

|

|

||||||||

|

||||||||||

Accidents and precautions for use |

|

To restore and repair a carbide lamp |

|

Catalogues of reference Models and types |

|

Bibliography & documentations |

|

Links |

|

Index & Detailed Menus |

mining lamps and safety lamps

![]()

- history - working - reference catalogues - history of lighting

History of the carbide lamps

-1-

|

|

-2-

|

|

-3-

|

|

![]()

Some dates

1815

Three English scientists invent the first lamps especially studied for the mine. Sir Humpfry Davy, William R. Clanny and Georges Stephenson will invent the first models of mining lamps which will not cease being improved until the 20th century.

1836

Davy the Edmund chemist, (the cousin of Sir Humphry Davy) will discover a gas very interesting and especially very luminous. He will baptize his invention of the acetylene name which associates the acetyl and ethylene, a

gas obtained thanks to the distillation of oil.

1862

Thirty years after its discovery, acetylene can be synthesized thanks to a French, the chemist (and politician) Pierre-Eugene BERTHELOT who manage to manufacture this gas starting from Carbone and of hydrogen under the action of an electric arc.

1892

Acetylene still belongs to chemistry, it will reach the industrial stage thanks to Henri Moisan who will find a process simple to manufacture calcium carbide. It will arrive at the fusion of coke and limestone at very high temperature in an arc furnace. To Canada, another researcher will obtain same the results: Lepold Wilson.

1893

With the industrialization of calcium carbide in Europe and in the United States, one will be able to develop autonomous lighting systems, generating dice miniature which very simply will domesticate this reaction between water and carbide: these are the acetylene gas lamp, that one also calls, carbide lamps.

![]()

In a few words

The carbide lamp is thus not strictly speaking

a "miner's lamp", although it was conceived with this use. Its exposed flame prohibiting it to be used in mines for coal which can make it terribly dangerous in contact with firedamp, it was used mainly

in the underground careers of extraction of stone, chalk, gypsum or for the culture of mushrooms (in Paris). Its sharp and luminous flame will naturally find applications military and civil, in particular for

[the lighting of the railroads], of the vehicles, or for a domestic use. ![]()

See also: [History of the lamps and lighting] - [History of mining lamps]

![]()

Description and working of the carbide lamps

|

CARBIDE LAMPS |

|

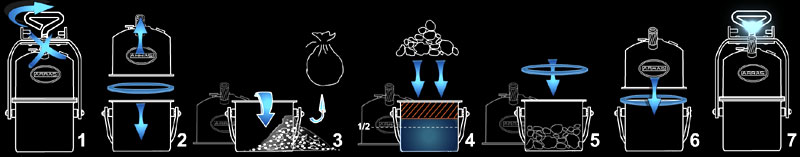

Description: The acetylene gas lamp consist of two tanks separated by a joint (Fig.1 and 2): the upper shaft is used as water tank, and the lower tank contains pieces of calcium carbide. In contact with water, the carbide produces a flammable and very luminous gas: acetylene. To maintain gas in the lamp, a system of closing is used. Generally, this one is composed of a metal framework - the clamp firmly fixed by a thumb screw, or sometimes a threaded rod located inside the lamp. They are separated by a seal which prevents that the gas does not escape. (Fig. 3 and 4) Working : A punch actuated by a small tap makes fall water, drop by drop on the carbide (Fig.5). The reaction is done between carbide and water (Fig.6); it will produce the gas acetylene which will fill the tank (Fig.7). Compressed in its hermetic tank, it arises by a very fine nozzle which concentrates the flame once lit (Fig.8). Dissolved by water, the carbide becomes lime, a grey powder, residue of this chemical reaction. NOTA : Models used as exemple on this website are mostly French lamps (Arras type). Most other types of carbide lamps have very similar uses. |

| 1 - Hook | ||

| 2- Screw | ||

| 3- Nozzle (burner tip) + nozzle protection + gaz pipe | ||

| 4- Clamp (or other closing system). | ||

| 5- Punch, also called (water valve, valve controler or regulator) + screw | ||

| 6- Stopper (cap or plug) | ||

|

7- Water tank (or water chamber) |

||

| 8- "Cup" or Flare fitting or (tapered flange) or (threaded) rings. plumber terms | ||

| 9- Seal (Rubber Gasket) | ||

| 10- Acetylen (gaz) in the carbide chamber | ||

| 11 - Carbide blocks |

Fig. 1 |

Fig. 2 |

Fig. 3 |

Fig. 4 |

Fig. 5 |

Fig. 6 |

Fig. 7 |

Fig. 8 |

Drawings © acethylene.com - All rights reserved

![]()

The acetylene gas lamp is generally provided with a hook to suspend it. The bicycle

lamps, helmet or cap's lamps have a back plate to hang them. These lamps generally manufactured out of plate buckled galvanized or are

galvanized (covered with tin). Some models are out of brass or sometimes out of aluminium. Those which are not intended for the fixing are quite simply posed: tables

lamps, of building site, or champignonnists are examples. ![]()

![]()

![]()

Basic elements

|

|

|

|

|

The ideal adjustment produces a regular and luminous flame. Underfed out of water, the flame yellows and decreases, it can even

"carbonize". Overfed, it consumes much carbide

and uses the nozzle unnecessarily. It is thus essential to find the adjustment of the punch allowing drop by drop regular producing

a "beautiful flame". |

|

These flames can take very different aspects, according to the drilling and the shape of the nozzle: the "butterfly flame", punt and very lighting formed by a

simple nozzle having a side slit or nozzle bored twice (double nozzle) (1), the round flame, economic and more adapted to a lamp having reflectors formed by a simple

nozzle with only one hole (2) and the double flame formed by a nozzle bored of two holes directed according to a particular angle (occasionally which can tend towards a

"butterfly flame" (3). Below: various types of flames produced by the acetylene gas lamp |

![]()

Illustrations © acethylene.com - All rights reserved - total or partial Reproduction prohibited.

(has and b) long and carbonaceous flames producing smoke: insufficient flow, too important nozzle or impurities in water. (c) very long luminous flame out of blowtorch: nozzle in overpressure or of insufficient diameter. (d) normal flame of combined nozzle. (E-F - G - H) comparison of flames butterfly (normals) for nozzles of 28l - 21l - 14l - 10l. (I) normal round flame for a nozzle of 7 liters (J) short and blue flame (oxygenated): lamp in the course of lighting. (K) flame in the shape of very small pearl: lamp in day before: to extinguish. (L) Double round flame for a nozzle with two drillings (double-nozzle). (m - N) Alternatives of flames butterfly which can take varied forms, in range or half-moon.

To discover an acetylene gas lamp - First use

These lamps having generally remained unutilised during many years, there are necessary to make sure that the lamp functions before lighting with. Before any attempt of use, or at the time of a purchase for a restoration, it is thus essential to check its state. Certain collectors of old objects also appreciate knowledge, even if they do not use them, that it are in a position to function.

|

|

![]() To open and release the screw pitches of a lamp.

To open and release the screw pitches of a lamp. ![]()

|

In cause of despair one can introduce a metal bar into the loop of the screw while turning in the opposite direction of the needles of a watch with force. A corroded screw can

break it is thus advised to use

the soft way. A vice can also appear useful for the best taken, in particular for the lamps with direct screwing (where the tank and the tank are screwed one in another without clamp). Not to be likely to damage the lamp, one can coat it with a thick rubber belting

which will ensure the catch in a vice, without leaving of mark in metal. |

![]() To check the sealing

of the lamp

To check the sealing

of the lamp ![]()

|

|

![]() To load and empty a carbide lamp

To load and empty a carbide lamp

![]()

Illustrations © acethylene.com - All rights reserved

|

To open an acetylene gas lamp whose flame is not extinct can cause a short explosion due to the release of the flammable gases which it contains. The first operation thus consists in starting electric lighting and to blow the flame of the carbide lamp. It is preferable to be provided as a preliminary with carbide of replacement to load the lamp, of a small plastic bag, of one nozzle and possibly of the small basic equipment emerges to clean the lamp. [Acetokit]

|

![]() Lighting and starting of the lamp

Lighting and starting of the lamp

![]()

|

It is thus checked that the lamp is well closed again and screwed. Initially nothing occurs, even if a flame is approached since the pressure is not yet sufficient so that the gas left by the nozzle. One or two minutes is enough so that the reaction is done completely. One can benefit from this moment to pass a flame around the joint for checking the sealing well: no flame must appear. In the contrary case, the lamp was badly closed again, or the joint is clogged.

|

|

If they thereafter are used, this completion will be useless, and will be able to even accentuate its clogging. One will be able to finally observe that the brass lamps oxidize naturally, and patinate more quickly than the iron lamps, and

than they are stained very quickly with the least contact with water. |

Maintenance of the lamps

|

|

|

|

|

|

Maintenance of Enamelled nozzle |

Maintenance of Joint |

Maintenance of Punch |

Maintenance of Tank |

Maintenance of Ferment (Callebonde) |

Stopper and Cup cover carbide |

![]() To maintain a carbide lamp

To maintain a carbide lamp

![]()

|

These old lamps are robust and require little care, one should not therefore forgetting to maintain them from time to time. To maintain the sealing:

[joined] and it [cup-(Flare

fitting)]

must be always smooth. In fact the parts are clogged most quickly. The nozzle requires a particular maintenance (see below). Incidentally, the outside of the lamp is cleaned with a dry rag or scotch-brite (green sponge for crockery)

used dry, to withdraw possible cloggings (mud, rust, lime). One can benefit from it to check that inside, the lower part of the water tank remains perfectly tight and runs only by actuating the punch. |

|

|

|

|

![]() Maintenance of the cup

(or Flare

fitting)

Maintenance of the cup

(or Flare

fitting)

![]()

|

|

|

|

|

|

![]() Maintenance of the

carbide tank

Maintenance of the

carbide tank

![]()

|

|

![]() The cup

(or carbide cover)

The cup

(or carbide cover)

![]()

|

|

|

|

![]()

Using advices and storage of Carbide

|

|

|

|

![]() With what does correspond the flow of the nozzles?

With what does correspond the flow of the nozzles?

![]()

|

The good choice of the nozzle is thus done according to the size of the lamp and its autonomy. A

clean nozzle on a well regulated lamp will make it possible the lamp to function

during 6 to 8 hours, even more, with only one load from

carbide and two filling of the water tank, without touching with the punch. |

Illustrations © acethylene.com - All rights reserved - total or partial Reproduction prohibited.

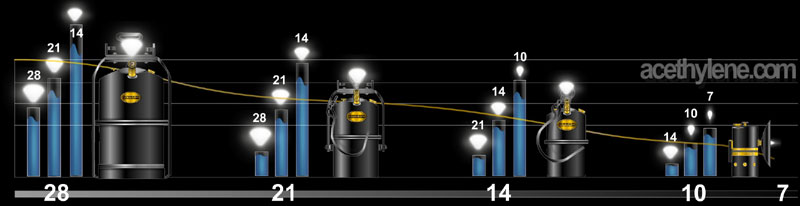

(1) Example: For a load of 300g, a lamp produces approximately 100 liters of gas acetylene. To know the duration of lighting, it is enough to divide this number by the flow to the nozzle. For this example, a nozzle of 21 Liters will provide 5 hours of lighting. One can thus estimate the flow of a nozzle if this one is not indicated above by applying the same formula: for carbide 300g, 100 liters of gases divided by the time of lighting will give the flow of the nozzle (for a "normal" water supply). This estimate can also be done "with the eye": the nozzles from 7 to 10 liters provide a flame of approximately 15mm, 14litres: 30mm, approximately 21 liters 40mm very lighting. this concept of flow of the nozzle is however very variable according to the water supply, and the wear of the nozzle, which will have while wearing, tendency to increase its flow.

(2) This diagram indicates the size of nozzle the most adapted for lamps of various capacities. The blue columns express the autonomy of the lamp: the carbide and water consumption necessary to obtain a satisfactory flow: a nozzle of large flow will require more water, and its autonomy will be thus weaker. Contrary a nozzle to more reduced size will form a smaller flame but during longer. The sizes of nozzles indicated into small are recommended for these types of lamps. The sizes (28, 21,14...) indicated approximately the nozzles best adapted for these sizes of lamps indicate. (See above for the explanatory detailed ones)

|

|

![]() Odor and the quality of carbide

Odor and the quality of carbide ![]()

|

|

|

|

![]() How to store calcium carbide

How to store calcium carbide ![]()

|

It is thus highly advised to open a barrel the least most often possible, by storing it in small reserves (approximately 1kg). With each opening, it will be also advised to fill the space of vacuum by foam, plastic with bubbles etc. which will decrease the quantity of air contained in a barrel.

Storage with the detail could be done in limp hermetic only held for this purpose (tupperware) or more simply of limp for instant coffee closed again well and filled to the maximum (always to limit the quantity of air).

Carbide pots exists

for this special use and can be found in the specialized stores or on Internet sites [Links].

|

|

The calcium Carbide is a flammable product which releases a gas considered as "explosive" as soon as it is under pressure. There thus exist security standards concerning its storage. Technically, the risk of explosion is weak and if these various instructions are respected, it is practically non-existent. In certain circumstances (fire, flood, compression, concentration in the air) it can nevertheless present a real danger, if these rules are not complied with. Any person using of carbide or the carbide lamps must know them.

Some advices of storage:

|

accidents and precautions

What one never should do?

- To open or dismount a lit lamp; this causes a gas release which can immediately ignite - To explore an unknown place being able to contain gas pockets, fuel emanations coming from surface, exposed to the naked flame of a lamp. - To check the level of the water of the tank by approaching a lighter of the site of the stopper - To aspire gas by the nozzle with the mouth, in the event of water increase (to withdraw moisture leaving by the nozzle) - To empty a lamp near the flame light of a candle or a lighter. - To use a jointless lamp, or with a joint obviously cracked, worn to avoid the joint of pot of jam - To sleep in a hammock located at the top of an open lamp which could of only one blow cause a sharp flame. |

Where to buy a carbide lamp and how to estimate its value

The carbide lamps are not rare, it is not a question either of the antiquities, oldest reach hardly 80 years, but more generally date from the Fifties. While seeking a little, one can thus easily find an acetylene gas lamp for a moderate price. There exist all kinds of models of course that the collectors of lamps or mining objects seek and who can reach important prices.

![]() To differentiate

and estimate a carbide lamp

To differentiate

and estimate a carbide lamp ![]()

|

|

|

|

|

Many models of lamps the SNCF used by, the more reduced lamp bicycle railroads of size generally having reflectors glazed, with each with dimensions incrustation of glass coloured in red and green, lamps of often recognizable

champignonnists to their horizontal handle out of wooden

etc. Of the new lamps, generally out of brass, are still sold by some factories throughout the world. All these lamps are of a cost slightly higher included/understood in a fork from 15 to 75 Euros for models in

perfect operating condition and of conservation. |

* The lamps Star known as "Draper" are declined in four models. Three traditional models are composed of a brass tank and a cast iron tank of a load of 300g and a total weight of 1Kg600. One can see here the model with side nozzle provided with reflectors, existing also with central nozzle or Parisian nozzle provided with a hook and a small cup protecting the hand from the flame and a rustic model with handle out of wooden. A last model intended for the engineers, Deputies Chiefs or supervisors was manufactured out of aluminium (instead of brass) and weighs only 800g.

|

|

|

In the United States, the production of lamps of small size was extremely important. These models used for the bicycles or clinging on the caps (Lucas - Justrite) are thus much more frequent than in Europe. These lamps manufactured in

very great number and declined in hundreds of models constitute thus the most important family of acetylene gas lamp |

These great types of families of lamps make it possible to distinguish them by their form, their use or their origin. There are of course quantities of models. Those can be differentiated by their features, their systems of closing, their general appearance. Do not hesitate with you to refer to [technical catalogues] or to [catalogues of reference] proposed over this site to obtain more precision.

![]() Where to find an acetylene gas lamp (in

France)

Where to find an acetylene gas lamp (in

France)

![]()

|

|

![]() Or to find spare parts for carbide lamps

Or to find spare parts for carbide lamps

![]()

|

|

![]() To identify a

acetylene gas lamp

To identify a

acetylene gas lamp ![]()

|

For the rarest lamps, there remain dedicated works with the acetylene gas lamps [bibliography] them

[specialized sites] on which he is often possible to ask the various collectors an assistance to this subject. |

|

|

|

|

The old nozzles consist of an enamelled end assembled on a ring brass, or aluminium (1). Generally their flow is indicated (7-14-21-28 liters) on the basis of nozzle. |

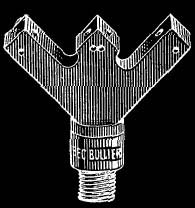

Double the nozzles in Y (combined) are subdivided in 2 branches diffusing of the flames of a low flow uniting to form only one of them. Certain models are designed to function out of night light. |

The Indian nozzles have the characteristic to be produced in small series. They produce variable flames out of tube, double flames and sometimes out of butterfly (rare). They do not adapt on the European lamps (2). |

The nozzle Petzl: it is about a head enamelled and machined by the manufacturer of material of speleology petzl. These nozzles offer variable flames according to their machining. They do not adapt on the old lamps (2). |

| With wear, an old nozzle can be used in an intensive way during one to two years. Its impact resistance is very low in particular in the event of fall on the enamelled part if they are not entirely covered by one protects nozzle. | The lifespan of a double nozzle in Y is similar to that of a nozzle but often one of the two "ends" wears before the other (and envisaged besides to be replaced). Its impact resistance is lowest because of its scale | These extremely fragile nozzles are very vulnerable to handling and imperatively require to be dismounted with a suitable key. With the shocks, it do not have any resistance. They seem to be nevertheless most resistant to wear. | Practically indestructible with the shocks, the nozzle Petzl wears nevertheless and is clogged very quickly while producing, sometimes as of the purchase, a carbonaceous smoke a nozzle machined very well form a flame spangle which perdure during approximately a year with an intensive use |

| Only available in old material or of occasion | Only available in old material or of occasion | New material available at JK Dey & sons |

New material available in all the shops of material of speleology |

| "butterfly flame" | Special flame | Flame out of tube, double flame and butterfly | Variable (flame out of tube or "butterfly flame") |

| Regular maintenance without more | Maintenance meticulous person | Very little maintenance | Very frequent maintenance not to carbonize |

| Consumption conforms to that indicated on the ring (21L = 21L), tending to increase according to wear | Consumption conforms to that indicated on the ring (21L = 21L), tending to increase according to wear | Very low, quite less consumption with that indicated. The 28L lights like a 21L and consumes like a 14L (!). The 14L lights celandine like a 10L (conso: 7L) | Consumption slightly higher than that indicated according to the machining of the nozzle |

| No the conical screw (of M8x100 with 6x100) being able to be screwed on a step "standard" right of 8x100 | No the conical screw (of M8x100 with 6x100) being able to be screwed on a "standard" step of 8x100 | No the screw English right of 6mm (does not correspond to the "standard" taps) [adapters] | No screw pitch, the entirely enamelled nozzle enchases in a screwed ring (diam: 8mm). [adapters] |

| Price: variable according to availability | Price: variable according to availability | Price: 1 to 3 Euros | 5 Euros |

| Availability: rare | Availability: Rare | Dispo: On order | Available in specialized store |

| Still used, these nozzles remain excellent if they are still in clean and protected well from the shocks with one protects nozzle. Their flame remains a reference. | Reserved for a use limited these splendid nozzles offer an incomparable flame but remain very vulnerable and fragile. | Although fragile, in particular to the assembly and disassembling, the "Indian" nozzles offer the best output, and especially are still available on the market. | Very robust model tested in speleology, the nozzle presents nevertheless disparities according to the quality of machining and a clear tendency to carbonize especially with wear. |

(1) The majority of these nozzles have a ring brass. Aluminium appearing with the more fragile use undoubtedly in particular with crushing but without incidence none on its effectiveness, depending

only on the quality of the enamel nozzle itself. ![]()

![]()

(2) These nozzles must be modified to adapt on old lamps: to see [adapters]

![]() Testing ground of the

most widespread lamps

Testing ground of the

most widespread lamps ![]()

|

|

|

|

Characterized by its round, often struck shape "of a mark Arras". The model more the current is closed by a strap bolt in the form of loop and the end of the punch finishes in the shape of flower. |

Slightly finer and higher than Arras, its upper part is bent. There are many alternatives but most current a screw in form of T has, and the end of the punch in the olive shape. |

Lamps of small sizes (approximately 10cm) among which one can distinguish the lamps from bicycle (Frenchwoman or American) as well as the model 115C manufactured by JK. One adapts nozzles of weak flows to it: 7 liters. |

Models JK 104 and 203 are easily recognizable, small and squat they exist out of brass or galvanized metal ringed by an elegant ring brass. Their characteristic is to be sold new. |

Very solid. Arras does not have practically any weak point. It will be noted however that depending on their state of conservation, some will tend to oxidize on the level of the tanks. |

Very solid and extremely resistant. Just like Arras they will be able to tend to oxidize since the layer of tin which protects it weakens with time. |

Sometimes fragile in particular on the level of the systems with screw and the nozzle |

Fragile in particular on the level of the system of screwed closing. Very fragile cups also, and is likely to lose the screws fixing the handle of the lamp. |

Autonomy 8 to 10 h, sometimes more. Its perfect volumes refer of Arras. The lamp ideally consumes 2 volumes of water for 1 carbide load. |

Autonomy 8 with 10 hours |

endurance 2 to 5 hours (According to the use and the nozzle) |

Endurance 6 to 8 hours |

Reliability: highly reliable. |

Reliability: the "military" models manufactured in great series are reliable, very slightly lower than "Arras" on the level of the design. |

Reliable over one rather short duration (the first hour) then more unstable taking into account very small capacity |

Models reliable requiring some adaptations to function correctly: disassembling of protects punch (clever but ineffective), and systematic use of a "sock" around the carbide load. |

Estimate: of 5 Euros (for a model to be restored) to 30 Euros for a clean and working model, sometimes more |

Estimate: of 5 Euros (for a model to be restored) to 25 Euros for a clean and working model |

Estimate: of 5 Euros (for a model to be restored) to 30 Euros for a clean and working model, sometimes more. |

Very low costs the purchase (25 E), the price increase considerably with the taxes and transport (50 to 60 E with the wholesale price). They can be negotiated between 75 and 100 Euros |

- All prices and estimations are indicatives -

![]() Where to find calcium carbide (in

France)

Where to find calcium carbide (in

France) ![]()

|

For an order in detail, It is also possible to acquire of it

with speleology clubs

and caving associations : try

[IUS]

(International Union of Speleology to get information about

your country)

. |

|

|

To restore and repair an acetylene gas lamp

These old objects, often forgotten, more or less require techniques to be given in operating condition or to be repaired. Without going until manufacture supplements of a lamp, here the manufactoring processes of the most current parts allowing to restore a lamp in bad condition or to replace the defective pieces. These repairs are not particularly complicated but they ask sometimes material, and especially a good knowledge of the working of the lamps. One will take here for example, the lamps of the Arras manufacture whose dimensions are relatively standard.

|

To restore or repair a lamp, a minimum of tools is essential. This list is not well on step exhaustive, but makes it possible to carry out most of the operations described then. To be equipped with less expenses, the chips and secondhand trades, make it possible to find, while clouding a little, all which one can need:

Metal, in plate, and tubes, in stems, iron or brass preferably (to avoid copper which can cause reactions with acetylene), recovered on old objects, old plumbings

etc |

|

It is much more interesting for a collector to acquire of a complete lamp having all its original parts. Nevertheless the purchase of an incomplete lamp could be used to replace certain parts, or, in certain cases, to function if all the

parts essential to its working are present.

Note that the cup covering carbide, is not essential and that to a lesser extent, the absence of protects nozzle, of stopper, even of reflectors do not prevent the

working of a lamp. |

|

|

|

For the coasts of the most widespread nozzles to also see [Test of the nozzles] |

(1) One distinguishes the dies (round clover part), tool intended to make the nets (not screw) represented in photo Ci above and the taps (long stem with a screw pitch) represented higher [here]. "Turns left" and carries it die are the handle which make it possible to encase these parts, to thread, or tap. For a tender material (brass, copper) only one tap (or die) is enough, but ideally these parts function by a set of 3: 1st trims (the rougher), the 2nd supplements, and 3rd (finisher) the screw pitch completes which one wishes to produce. This tool is used with a vice (even small) and does not require any competence, except being careful and regular in its gesture.

(2) The references of the taps are sometimes variable: 8x1.5 can be indicated M8-1.5 but also 8x15 or 8x150

(3) Old format relatively rare to find.

|

Lamp of the type I: charge 250g - Height 15 cm - Tare weight 1100g - Diameter of the joint 100mm - Intensity (for a nozzle of 14L): 18 candles (lux) - Duration of lighting 6 with 8:00. Lamp of the type 3: charge 450g - Height 17 cm - Tare weight 1300g - Diameter of the joint 115mm - Intensity (for a nozzle of 14L): 18 candles (lux) - Duration of lighting 10 with 12:00. Lamp of the type 5: charge 900g - Height 22 cm - Tare weight 1700g - Diameter of the joint 100mm - Intensity (for a nozzle of 14L): 18 candles (lux) - Duration of lighting 14 with 16:00. |

![]() Comparative table of the various sizes of lamps

Comparative table of the various sizes of lamps

![]()

![]() To manufacture and maintain a

joint

To manufacture and maintain a

joint ![]()

|

|

![]() To manufacture one protects nozzle

To manufacture one protects nozzle

![]()

|

|

|

|

|

|

![]() To manufacture a clamp and a screwed plug

To manufacture a clamp and a screwed plug

![]()

|

It is also possible to remake a clamp, starting from stems punts curved out of U, reinforced by parts riveted on the level of the screw pitch. The interest to manufacture such a part is tiny, in measurement or one can easily recover a

clamp on a lamp out of use. But this process can be useful in particular to manufacture its own carbide lamp. It will be then necessary to have a drill press to bore with precision the hole which will be used as step of screwed plug. |

|

|

![]() To manufacture

adapters of nozzles

To manufacture

adapters of nozzles ![]()

|

|

![]() Replacement of the hose connection of the door nozzle

Replacement of the hose connection of the door nozzle ![]()

|

|

![]() To resolder a small brass plate

To resolder a small brass plate

![]()

|

|

![]() To stop a hole in an acetylene gas lamp

To stop a hole in an acetylene gas lamp

![]()

|

|

The term of ?welding? used here, gets along with the general direction, the technique used is precisely a ?joining? of two pieces of metal with welding.

![]() To change the plate of the bottom of the tank

To change the plate of the bottom of the tank

![]()

|

|

|

|

As one saw previously, the old carbide lamps are not only objects of exposure or collection. Some still quite simply use them for lighting. The robustness, the charm of these old objects and their moderate cost make of them lamps still very appreciated by the visitors of careers, speleologists or urban explorers visiting of the obscure places. They are sometimes transformed or modified to be used as generator with acetylene (connected to helmets), offering qualities close to the lamps of modern speleology. While using them, can arrive some incidents, sometimes impressive but without gravity, generally due to a misuse or a simple clogging.

|

The lamp spits of water and ?coughs?. Generally, the lamp is too charged out of carbide. The lack of space of air leads the steam to go up by the nozzle. (This one does not evaporate the vapor with heat which it releases.) The water wedged in the flue, prevents gases from freely passing: it is then necessary to reopen the lamp and to withdraw carbide or lime to release it and drain the nozzle by cleaning it and in blowing inside (not to aspire if possible to avoid inhaling gas).

The gas increase by the tank is dangerous. It is important never not to approach a flame of the stopper of the water tank. When the lamp is slightly stopped or in overpressure, the gas excess escapes where it can: by the joints if those are worn, or by the water tank. This tank is more or less closed by the stopper, the gas thus concentrates in the water tank of the lamp and can thus ignite by approaching a flame. This can also indicate that the bottom of the tank is porous, that the hose connection of exhaust of gas is bored or that it has an escape on this level.

This can arrive but is not a catastrophe if one acts quickly in a sufficiently broken down place. It can become much more dangerous in confined place. It is quickly necessary to extinguish the flame into blowing violently on the part of

the joint which takes fire, then extinguishing the lamp. Once in safety, it will have necessarily to be opened to find the origin of this escape (often a problem of joint or cup

-Flare

fitting-). The pressure in the tank is not important, and the lamp is not likely

"to explode".

|

|

A black smoke escapes from the nozzle by leaving a particular soot odor. Either the nozzle is cracked or worn, or too soiled water causes this reaction. Sometimes a simple cleaning is enough, generally it is necessary to change the nozzle. It can be possible to resolder it if it is just split on the level of the brass ring (with a simple blow lamp). These soot inhalations are very harmful and infiltrate in the lower parts of the lungs. This same phenomenon can also occur by using a nozzle of a too important flow or when the water flow is too low.

The flame is blue and whistles: this normal reaction releases the oxygen of the tank at the time when one has just reloaded it. Acetylene "pushes" the air by forming a small very sharp but not very luminous non luminous flame. Little by little, the air is released and form carburizes it a very lighting luminous flame. It can also happen that the lamps make various small noises due to the flow of water, the pressure... It is said whereas they "sing".

The flame is very small, whereas it has just been charged out of water and carbide: Either water does not run out (punch), or there exists an escape. After 2 or 3 minutes, the lamp goes up in pressure. If that is not done, the flame

remains size of a pearl. The nozzle is stopped (in this case to clean it with a cure nozzle), the lamp is not correctly closed or has escapes (one can check it while passing a lighter on the contour of the joint). To also check that there is enough water in the tank.

|

|

Another type of escape can also be solved, always temporarily if level of the nozzle, the screw pitch has a tiny play which causes a light escape, this one can be repaired with a simple plastic

bag. To extinguish the lamp and to withdraw the nozzle. To stretch a band of the bag which will be rolled up by tightening it very extremely on the screw pitch then to screw up the nozzle. It will form a joint of fortune (as

a band of Teflon used in plumbing) which will hold one moment. |

Catalogues of models and photographs

![]()

|

|

|

||||

Catalogue reference - carbide lamps -

|

|

Catalogue reference 2 - carbide lamps - (work in progress) |

|

Catalogue photographs flash |

|

Catalogue photographs flash |

* Galleries in Flash

The loading of these galleries require the remote loading of flashplayer

If you use another navigator or mac, check that it is well configured to see the pages in flash.

![]()

Technical catalogues

|

|

|

|

|

|||

Closing by direct screwing |

|

Direct closing by screw in lower part |

|

Closing by multiple screws |

|

Closing with central bayonet |

Closing with bayonet at the bottom |

|

|

|

|

|

|||

Closing by direct screwing on the top |

Closing by clamp and screw with the top |

Closing by clamp and sliding screw |

Closing by clamp and screw in lower part |

Closing eccentric |

MODELS OF LAMPS BY TYPES OF HOOKS

|

|

|

|

| German hook | Belgian hook | Hook of Saint-Etienne | Mine hook |

| Hook with double point very widespread in Germany and adoptee by some French exploitations of the center and the South then taken again by a great number of French manufacturers. | Round and simple hook in form of "S" formed of a round stem to the flat end employed in Belgium, adopted by the mines of the areas of North and Pas-de-Calais (France) | Formed hook of a double point prolonged by a long right stem. it is the hook of the Collieries of St Etienne and the various companies of the basins of the Loire and midday | Elegant hook in the shape of pickaxe used on the oil lamps known as -Raves-, formed a length right handle ending in a small pickaxe used on special lamps. |

MODELS OF LAMPS BY TYPES OF NOZZLES

![]() Models of lamps per type of Nozzles

Models of lamps per type of Nozzles

![]()

|

|

|

|

|

| Parisian nozzle | Central nozzle | Bent nozzle | Side nozzle (high) | Side nozzle (Low) |

| The nozzle fixed on the top of the tank forms an angle of 45°. It is the format usually employed on the lamps of the manufacture of Arras | The nozzle is fixed on the top of the tank. It offers the advantage of protecting the flame well from the contact It is also format employed for the mining lamps or table. |

The Nozzle located at the top of the lamp forms an elbow directed upwards. It is a format frequently taken again on the lamps known as "military" --LaFrançaise--. |

The nozzle is established on the upper shaft and crosses the water tank to leave on with dimensions one. It is generalized on the German, English and American lamps | The nozzle directly fixed on the tank is often supplied with reflectors. One finds this format on a great number of European lamps, with or without bent sleeve. |

![]() Models of lamps per use and origin

Models of lamps per use and origin

![]()

|

|

|

|

| French portable lamps | Lamps of champignonnist | US hat lamps (cap' S lamp) | German acetylene gas lamp |

This type of lamp distributed by many manufacturers in France make of it a model enough courrant. It has a multitude of alternatives. It is a simple lamp a height of approximately 20cm often provided with a hook and of two tanks of equivalent sizes. |

This recognizable model with its handle out of horizontal wooden and its central nozzle. Used in the careers recycled in mushroom beds, this lamp is more rarely and often in bad condition of the wood degraded by moisture. |

This lamp of very small size is often of American origin produced for the majority by the company "Justrite" and declined in many models. The body of the lamp is generally out of brass striated with several levels with a vertical nozzle. |

These robust models of a size of 10 with 15cm were mainly produced by the company "Friemann & Wolf". They generally exist in a brass version, having a clamp with hook, reflectors elaborate and a hook without swivel. |

|

|

|

|

| Lamps of tables | Torch of help "of firemen" | mining lamps | Lamps of bicycle and auto-cycles |

| The lamps of tables are elegant and decorative models out of brass curvature of very round forms and a relatively important capacity. A central nozzle protects the flame from the contact and allows a peripheral lighting. They are intended to be posed and thus are generally stripped of hook. | The "lamp of fireman" is a kind of torch made up of a handle out of wooden. It fits in a sleeve supporting an acetylene gas lamp of large size. Its two nozzles provide a flame of size comparable with a torch and lighting. These models are relatively rare. | The "mining lamp" acetylene regains the general shape of the mining lamps has gasoline and to oil with flame protected by glass and bars from metal. One will find among the most known models, the Carmaux lamp and lamps KP of Arras like certain Wolf lamps. | The lamps of bicycles of small cuts and have the characteristic to have reflectors complete protecting the flame from the wind and the rain with share and others of the incrustations of green and red coloured glass. An attachment unit to spring adapts on the machine which it lights. There exists innumerable variates about it. |

Lanterns and lamps the "SNCF" (French Railroads)

![]()

These lamps which one generally indicates under the name of "lamps the SNCF" were manufactured and used by the Railroads French and German, (in particular during the war). These Ferroviaires lightings constitute a complete family of carbide lamps: lanterns. They are the subject of a special page [carbide lamps of the railroads].

safety lamps

![]()

These lamps often confused with the carbide lamps are generally indicated without distinction under the generic name of "mining lamps". More precisely these lamps are especially used for the exploitation of the mining layers and in particular of coal.

To see all about mining lamps :

[mining lamps and safety lamps]

CATALOGUE REFERENCE OF NOZZLES

The models exposed below are distinguished in two categories: simple nozzles, and combined nozzles with two branches known as "double nozzles". Some of these nozzles are provided with a system of in-draught with side entries which incorporate the air in the gas acetylene before combustion avoiding the soot deposit thus, thus increasing their lifespan. These nozzles cannot however burn out of night light except for the nozzle //Bray// Elta (and of its derivative in simple nozzle: Ota).

|

|

|

|

|

|

Nozzle -Lecoq- Ref. 560 - 7 to 56L |

Nozzle -Lecoq- Ref. 580 - 7 to 56L |

Nozzle 800-3 Unknown manufacturer |

Nozzle 800-2 Unknown manufacturer |

Nozzle 800-1 Unknown manufacturer |

|

|

|

|

|

|

Nozzle combined BULLIER- -Lecoq- Ref. 1087 |

Nozzle combined BULLIER- -Lecoq- Ref. 1051/1081 - 14 to 35L |

Nozzle

//UNION// For cycles |

Nozzle //UNION// Simple |

Nozzle combined BULLIER- -Lecoq- Ref. 1056 - 30 to 50L |

|

|

|

|

|

| Nozzle combined

//BRAY// ELTA - 21 to 35L |

Nozzle

//BRAY// RONI - 7 to 35L |

Nozzle combined BULLIER- -Lecoq- Ref. 1040/1050 - 10 to 35L |

Nozzle

//BRAY// BETO - 28 to 56L |

Nozzle combined

//BRAY// LUTED - 17 to 35L |

|

|

|

|

|

|

Nozzle //BRAY// CETO - 7 to 28L |

Nozzle ACETYL Unknown manufacturer |

Nozzle BRAY DETO - 7 to 28L |

Nozzle CANDLE Unknown manufacturer |

Incandescent nozzle relighting the flame when it is puffed up |

|

|

|

|

|

|

Nozzle combined BULLIER- -Lecoq- Ref. 1080 - 10 to 35L |

Nozzle combined

//BRAY// CYKA- 17 to 35L |

Nozzle combined

//BRAY// FINAX- 7 and 10 1/2L |

Nozzle //BRAY// VIKA- 31/2 - 51/2 and 7L |

Nozzle combined

//BRAY// STEATITE - 21 to 35L |

One will find very similar models, to see identical, manufactured in Germany (Frieman & Wolf) and in the United States (Justrite).

Nozzles, will depend the flame which will be provided by the lamp: to also see the various types of flames

documentation and remote loadings

-Mostly in French-

![]() Topo acetylene gas lamp I of [explographies]

Topo acetylene gas lamp I of [explographies]

![]()

![]() Topo acetylene gas lamp II of [explographies]

(227 ko)

Topo acetylene gas lamp II of [explographies]

(227 ko)

![]()

![]() Excerpt from the Original catalogue Arras

(674 ko)

Excerpt from the Original catalogue Arras

(674 ko)

![]()

![]() Original blue

drawings of manufacture Arras

(50 ko)

Original blue

drawings of manufacture Arras

(50 ko)

![]()

![]() Original blue

drawings of manufacture Arras Carmaux(58 ko)

Original blue

drawings of manufacture Arras Carmaux(58 ko)

![]()

![]() Handwritten notes of manufacture of Arras manufacture for the design of the Carmaux lamp

Handwritten notes of manufacture of Arras manufacture for the design of the Carmaux lamp

![]()

![]() Original notes of the dimensions and threadings Arras

(109 ko)

Original notes of the dimensions and threadings Arras

(109 ko)

![]()

![]() Catalogue

/Manufrance/ (146

ko) *

Catalogue

/Manufrance/ (146

ko) *

![]()

![]() Catalogue Wendling for cycles and cars

(456 ko)

Catalogue Wendling for cycles and cars

(456 ko)

![]()

![]() Catalogue Luxor

for bicycle lamps

(354 ko) *

Catalogue Luxor

for bicycle lamps

(354 ko) *

![]()

![]() Tom Moss notice showing

how to use carbide lamps (English)

(267 ko)

Tom Moss notice showing

how to use carbide lamps (English)

(267 ko)

![]()

(exerpt from : www.caves.org )

![]() Minex

Lamps notice (English)

(437 ko)

Minex

Lamps notice (English)

(437 ko)

![]()

![]() Original notice of the acetylene gas lamps Arras

(125 ko)

Original notice of the acetylene gas lamps Arras

(125 ko)

![]()

![]() Catalogue Hendrie et Bolthoff

(692 ko)

Catalogue Hendrie et Bolthoff

(692 ko)

![]()

![]() Absolute

link

Absolute

link

![]() Relative link

(n°2) -

Relative link

(n°2) -

![]() /AcrobateReader /

/AcrobateReader /

![]()

Carbide lamps - mining lamps

You will find here a broad choice of the principal books about carbide lamps and mining lamps.

Many commercial websites propose to order them on line.

|

|

|

|

|

|

|

Carbide Light Dave Thorpe |

|

The miners flame light book Henry has. Pohs |

|

American Miners Carbide Lamps Gregg Clemmer |

|

Lampes desMines et des Carrières Daniel Munier (DMI) |

|

||||||

|

|

|

|

|

|

|

Lumières dans la mine Marcel Humbert-Labeaumaz |

|

La Lampe de Mine Michel Vernus - Philippe Markarian |

|

Kuckuck Frosch Granate Walter Tanke (1992) |

|

Karbidlampen aus Schweden Karl Heupel, - Dieter Stoffels |

|

||||||

|

|

|

|

|

|

|

160 Jahre Wetterlampen Peter Hubig (1983) |

|

Banské Lampy - Grubenlampen (1995) Rudolf Magula - Tibor Turcan |

|

Of Bergmanns Geleucht Werner Börkel - Woeckner Horst |

|

Lumières dans la Mine(1994 catalogue) G. Ceccarelli, M.C. Dupont, T.Veyron |

|

||||||

|

|

|

|

|

|

|

Lampes de Mine(1994) Michel Dupont - Gil Lebois |

|

Luces in mow mined of Asturias Alberto Vilela Campo |

|

Les lumières dans le Nuit M.C. Dupont (1983) |

|

Antique Mining Equipment David Pearson - Ron Bommarito |

credits

:: nexus ::

Thanks to

Kalimero - A.G. - Delhomme - Dominique Paris - JP Parisot

- pages translated by a translation software -

www.acethylene.com - www.explographies.com

- www.geopedia.fr

Texts, photos and documents

copyrighted.

© explographies.com - All rights reserved - Publication, total or partial reproduction prohibited.

![]()

![]() detailed menus

detailed menus

![]()

explographies. - cube - acethylene - igc-maps - quarries & catacombs - photographs - atlas 1855 - cartographies - geology - topos & history - room K - geopedia

![]()